In hydroponics, ATC or automatic temperature compensation is an extremely important factor when growing hydroponically, as water temperature changes frequently.

The temperature of a nutrient solution affects EC readings, often leading to inaccuracies that negatively impact overall plant growth. Automatic temperature compensation helps us to get more accurate readings taking into consideration the effect of temperature on the EC.

Let’s find out what automatic temperature compensation is, and how it can help you grow your hydroponic crops much more effectively.

What is Automatic Temperature Compensation (ATC)?

ATC or automatic temperature compensation is a special feature that modern EC meters, TDS meters, pH meters, and other measuring devices have. The ATC calculated the effect of the temperature on the reading and adjusted the reading according to the pre-programmed formula.

Automatic temperature compensation allows far more accurate EC and PPM measurements, automatically recalibrating the measurements based on a predefined reference temperature, commonly set at 77°F (25°C), aligning with the ideal conditions for a vast majority of hydroponic crops.

See How Growee Can Save You Time By Automating Your Plants Feeding

Water pH – Automated pH Up and Down Control

Nutrients Mixing – Automated Nutrient Dosing with Target EC / PPM Control.

Control From Anywhere – WiFi Connection and mobile App

How Does Automatic Temperature Compensation Work?

Although it may sound complicated, automatic temperature compensation works by using a simple thermometer or temperature sensor to measure the temperature of the nutrient solution. The ATC-enabled device then used a predetermined formula to provide more accurate pH, EC, or PPM readings.

It adjusts the values to what they would be at the reference temperature, which as mentioned above, is usually 77 degrees. This allows growers to obtain accurate EC readings without having to do manual calculations, which are rather difficult.

In simple words, The controller/meter program collects the solution EC and temperature reading, according to the difference between the current temperature of the solution and the reference solution (typically 77F or 25c) it changes the value of the EC, adding or deducting EC points.

Why Does the Temperature Change the EC/PPM Reading of the Water?

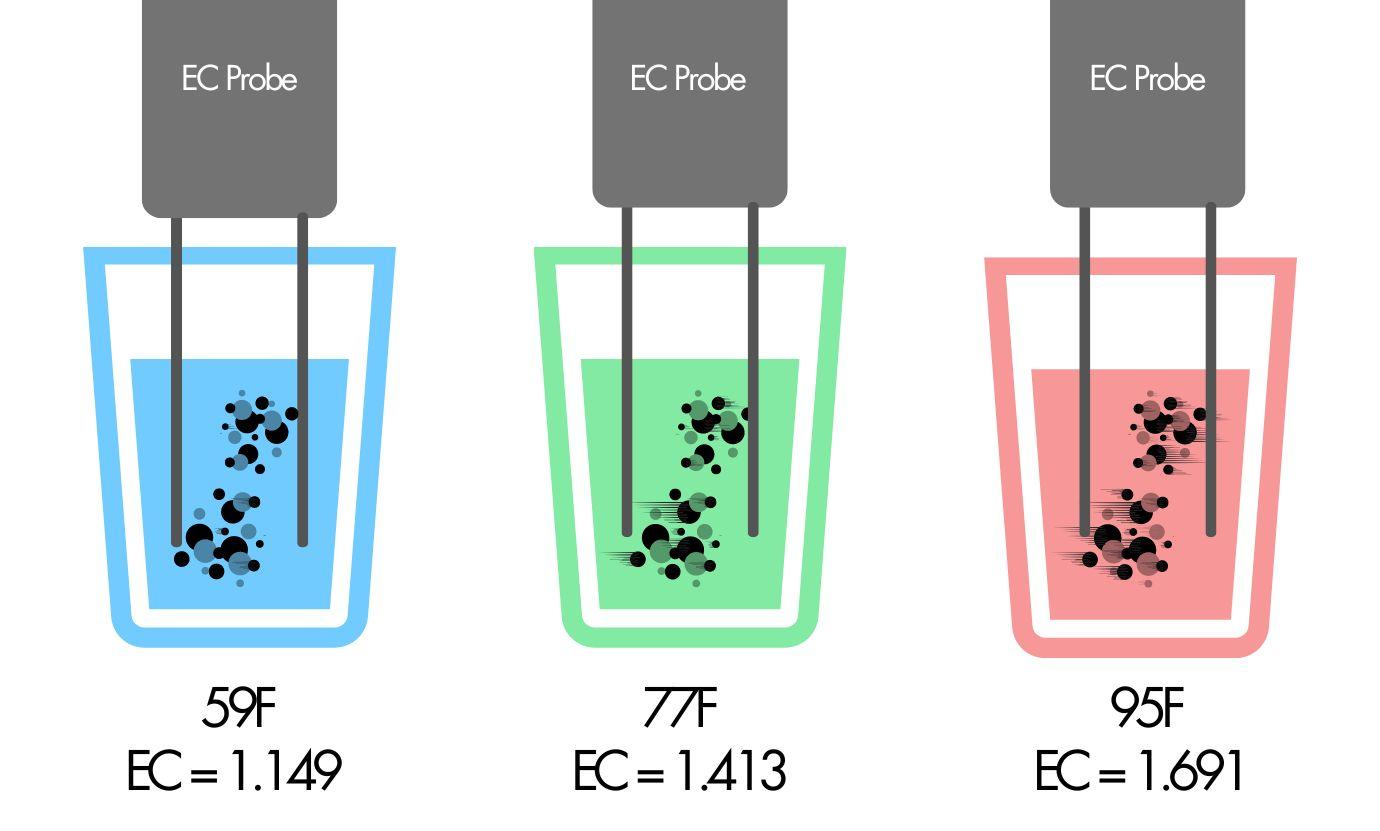

The reason why temperature affects the EC and PPM readings of the water is because the higher the temperature, the more mobile the ions or molecules within.

In other words, if the temperature is high, the ions and molecules in the nutrient solution will be highly mobile, providing higher EC readings.

On the other hand, if the temperature is very low, those ions and molecules move much slower and are less mobile, which can lead to low EC readings.

Without an ATC meter to compensate for these temperature differences, EC readings can be highly inaccurate.

Let’s consider a simpler example with a cup of tea. When your tea is hot, the sugar you add dissolves quickly and easily, because the heat gives the sugar molecules more energy to move and spread out. This is like when the temperature is high in a nutrient solution, allowing ions to move freely and leading to higher EC readings.

Now, if your tea cools down, the sugar dissolves more slowly and may even leave some undissolved at the bottom. In cooler conditions, ions in the nutrient solution move slower, similar to the sugar, resulting in lower EC readings.

How Does the ATC EC Meter Compensate for Temperature Effect?

An ATC meter uses a special mathematical formula or algorithm to compensate for the temperature. It takes the current EC reading at the current temperature. It then automatically plugs these figures into its formula, which it uses to adjust the EC reading to be in line with the reference temperature.

Simply put, if the temperature of the nutrient solution is below the reference temperature of the meter, the algorithm will work to adjust the EC readings to what they would be at the higher reference temperature, and vice versa. This correction is otherwise known as the correction factor.

For example, if the ATC uses a standard compensation factor (which varies depending on the meter and the type of solution but is often around 2% per °C for many nutrient solutions), it will adjust the reading upwards to account for the lower temperature. The adjustment would account for the 10°C difference from the standard (25°C – 15°C = 10°C).

Here’s a simplified calculation to demonstrate this adjustment:

- Adjusted EC=Actual EC+(Actual EC×Temperature Difference×Compensation Factor)

- Assuming a compensation factor of 2% per °C.

- Adjusted EC=1.5+(1.5×10×0.02)

- Adjusted EC=1.8 dS/m at 25°C

the ATC would adjust the reading from 1.5 dS/m at 15°C to approximately 1.8 dS/m to reflect what the EC would likely be at the standard temperature of 25°C.

Real Life Example of Using ATC in EC Meter Calibration

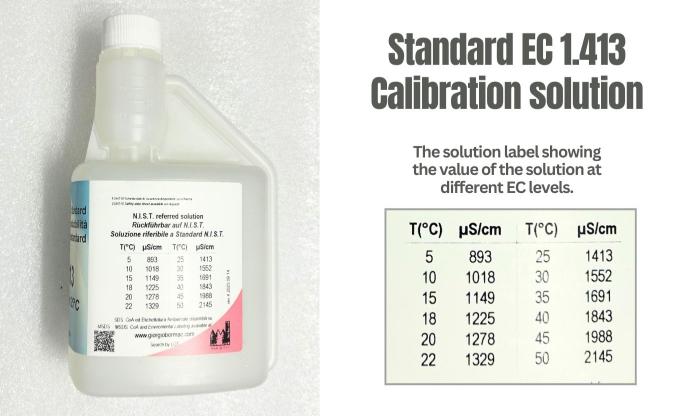

Without Automatic Temperature Compensation (ATC), if you place an EC probe in a standard calibration solution with an EC of 1.413 (measured at 25°C) but the actual temperature of the solution is 15°C, the reading will likely show lower than 1.413 due to the reduced mobility of ions at cooler temperatures.

With ATC, however, the device adjusts the reading to show the correct EC of 1.413, as it compensates for the temperature difference, ensuring the reading matches what it would be at the standard temperature of 25°C. This means, that despite the actual cooler temperature, the ATC ensures you get the accurate EC value as if the solution were at the ideal temperature.

Benefits of Using ATC

There are two main benefits of using automatic temperature compensation in hydroponics.

Accuracy

The fact is that without ATC, your EC measurements just won’t be very accurate. Having excessively low or high EC levels in your nutrient solution can lead to some really serious problems, whether nutrient deficiencies or nutrient burn. If you expect to grow the best crop possible, providing your plants with the ideal level of nutrients is essential.

Consistency

Using an EC meter with ATC is also beneficial because it standardizes all readings to the same reference temperature. This allows for much greater consistency with readings over a longer period, which ultimately makes life much easier when feeding your plants.

How to Choose an EC Meter with Automatic Temperature Compensation?

There are four main factors to consider when purchasing an EC meter with ATC: accuracy, range, calibration features, and price.

Accuracy

EC meters with 80C should be extremely accurate. This is a reading that you’ll be able to find on the product label. For hydroponics, an error margin of ±1% is acceptable, although no more. The smaller this margin is, the more accurate the readings.

Range

Also, pay attention to the range of readings that the unit in question can provide. The wider the range is, the more flexible the meter is when growing various plants and crops. An ideal range is 0.1 to 10.0 mS/cm.

Calibration Features

The meter in question should allow you to calibrate the unit. Calibration is very important as this allows you to maintain a high degree of accuracy over a prolonged period of time. Some meters require manual adjustments to be made, although those that have automatic one-touch calibration are best.

Price

Do also keep your budget in mind, although you often get what you pay for. So, we would recommend going for a model that is accurate, durable, and easy to use, over one that is purely cost-effective. Yes, a good price is always nice, but it’s not the main thing to look out for.

How Does the Growee Hydro Master Use ATC?

The Growee HydroMaster is a smart hydroponics controller that acts as an EC meter that allows for live pH and TDS tracking thanks to the Growee App.

The HydroMaster can detect water temperature while also taking EC and pH readings. It includes a built-in automatic temperature compensation function that adjusts the reading based on the predetermined reference temperature.

Thanks to this, it is by far one of the most accurate and useful hydroponic EC and pH meters that your money can buy.

Conclusion

The bottom line is that without accurate EC readings, growing hydroponic plants is nearly impossible, and without ATC, getting accurate readings is just as hard. That’s why something like the Growee HydroMaster with integrated ATC is so useful!

FAQ

Why is Temperature Compensation Necessary for Conductivity Measurement?

Temperature compensation is necessary for conductivity measurement because the temperature of a nutrient solution affects the readings, with both excessively high and low temperatures leading to inaccuracies. Automatic temperature compensation accounts for these temperature differences.

How Do You Calculate Temperature Compensation?

The standard calculation for temperature compensation is EC25 = EC measured × [1 + α (T measured − 25)]. Simply plug your readings into the formula and make the calculation.

What is Standard Temperature Compensation?

The standard that most ATC-enabled meters use is 77 degrees Fahrenheit or 25 degrees Celsius.

Can I Use an EC Meter Without ATC?

Yes, there are many EC meters out there that do not have automatic temperature compensation. However, the issue with these is of course that they are not nearly as accurate as those units that do have automatic temperature compensation.

How Accurate is ATC?

How accurate automatic temperature compensation is really depends on the specific meter itself, as some are built much better than others. However, the HydroMaster is one of the most accurate units in the world, with a margin of error well under 1%.